Factors Affecting Boat Engine Service Costs

Several components influence the cost of servicing a boat engine. First and foremost, the type of boat and engine plays a critical role. Larger boats with more complex engines generally require more labor and higher costs.

Labor Rates: Who performs the repair significantly alters the expenses. Professional service costs substantially more than do-it-yourself maintenance.

Type and Extent of Service: Routine maintenance such as oil changes tend to be less expensive. However, in-depth repairs, such as replacing parts of the engine, will drive up the price.

Geographical Location: Service rates vary by region. Coastal areas with a high volume of boats may offer competitive pricing, while inland regions could be more expensive due to limited service options.

Material Costs: The price of parts and materials, from filters to specialized oils, impacts the overall service cost. High-quality or brand-specific parts usually cost more.

With 20 years of boating experience, the following cost breakdown provides unique insights into the maintenance expenses:

- Oil Change: $100 – $200

- Filter Replacement varies depending on the filter type.

Experts also point out that boat owners can anticipate spending 5% to 15% of the vessel’s original purchase price on annual maintenance. However, these costs can fluctuate based on the factors mentioned above. Additionally, the need for diagnostic services to identify issues with the engine can add to the total cost.

Remember, diligent owners can often save on costs by accurately diagnosing the issue and seeking the most cost-effective service options available to them.

Types of Boat Engine Services

With two decades of boating experience, one understands the importance of regular maintenance and timely repairs to keep a boat’s engine running smoothly. Boat engine services vary significantly, from routine tune-ups to comprehensive overhauls, each with particular processes and associated costs.

Routine Maintenance

- Engine Oil Change: Essential for engine health, typically every 100 hours of operation.

- Gear Lube Replacement: Prevents gear issues, recommended annually.

- Fuel Filter Change: Helps in maintaining engine efficiency.

- Water Pump and Thermostat Check: Critical for cooling system function.

- Engine Tune-Up: Adjusts engine for optimal performance.

The cornerstone of a well-maintained boat engine is routine maintenance. This encompasses the regular service jobs that keep an engine running at peak efficiency, such as oil changes, gear lube replacement, and inspections for various components like fuel filters, water pumps, and thermostats. These tasks are typically performed on a schedule based on hours of engine use or at specific intervals, such as annually.

Minor Repairs

- Replacement of Belts and Hoses: They can become brittle and need periodic replacement.

- Electrical System Repairs: Include troubleshooting and fixing wiring issues.

- Ignition System Service: Involves spark plugs and ignition wires maintenance.

Occasionally, a boat engine will require minor repairs, which can stem from regular wear and tear or as preemptive actions to avoid larger issues. These can include the replacement of worn belts and hoses, repairs to the electrical system, and maintenance of the ignition system.

Major Overhauls

- Complete Engine Rebuild: Involves disassembling, inspecting, and replacing significant engine components.

- Repowering: The process of replacing an old engine with a new one.

When serious problems arise or after extensive use, an engine may need a major overhaul. This comprehensive service might entail a complete engine rebuild, where an engine is disassembled, thoroughly inspected, and worn parts are replaced, restoring it to like-new condition. In some cases, repowering, which means replacing the engine entirely, might be the most cost-effective solution in the long term.

Parts and Materials

When servicing a boat engine, a technician considers the cost of parts and materials, which can vary by engine brand and type. They often replace the oil filter and engine oil during routine maintenance. An oil change for a 150HP outboard engine, for example, can range in parts cost between $8-$20 for the oil filter.

- Typical replacements during service may include:

- Oil filter

- Spark plugs

- Fuel filter

- Impellers

- Anodes

Prices for these items vary depending on the provider and type of material selected. An outboard maintenance service that includes impellers typically incurs a higher cost due to the additional parts required.

In addition to these specifics, the quality of materials chosen plays a crucial role in the longevity and performance of the engine. High-quality, marine-grade materials typically cost more upfront but can provide greater value in the long run due to durability.

Here’s a breakdown of the parts that may be involved:

| Part | Average Price Range |

|---|---|

| Oil Filter | $8 – $20 |

| Spark Plugs | $2 – $15 each |

| Fuel Filter | $15 – $100 |

| Impellers | $20 – $100 |

| Anodes | $15 – $50 |

Bear in mind that these prices do not include labor costs, which are separate and also vary depending on the service provider. Overall, the goal is to ensure a boat engine is maintained with the best parts and materials available, balancing cost with the benefit obtained.

Labor Costs

Boat engine maintenance can vary widely depending on the region and the complexity of the services required. Labor fees for marine technician service typically range from $70 to $120 per hour. These fees are similar to those charged by automobile dealerships, reflecting the specialized skills required for marine engine service and repair.

Boating enthusiasts with two decades of experience often note that labor is one of the major expenses in boat engine servicing. For instance, a full service that includes replacing impellers may cost around $1000 per engine based on a standard labor rate. Without the inclusion of impellers, the cost could be approximately $500.

-

Oil Changes: An oil change done by a professional may cost between $160 and $190, including supplies and labor.

-

Major Services: The 100-hour service, a common milestone for maintenance, typically costs between $250 and $500 per engine for labor.

Maintenance costs can also differ based on the type of boat, the size of the engine, and the frequency of use. Boats.net provides guidance on how do-it-yourself approaches can differ in cost compared to professional services, noting the substantial savings when owners undertake simple maintenance tasks themselves.

To minimize costs without compromising on quality, boat owners may choose to learn basic maintenance skills or selectively use professional services for more complex tasks. Boating Valley breaks down the annual costs, highlighting the importance of regular washing and cleaning, which can also be part of maintenance routines.

Understanding these labor cost factors is essential for boat owners to effectively budget for the ongoing care of their marine engines.

Service Provider Variations

When it comes to boat engine service costs, they can vary widely depending on the service provider. An experienced provider with over 20 years in boating will likely offer a comprehensive service, albeit at a potentially higher rate, while a less experienced mechanic might offer competitive pricing to attract business.

Location:

Service rates can be influenced by geographic location, with higher expenses associated with metropolitan areas or prominent marinas.

Expertise:

- Master Mechanics: They command a premium for specialized work, such as servicing high-performance engines.

- General Technicians: Usually offer more affordable rates for routine maintenance tasks.

Facilities:

Providers that have access to advanced diagnostic tools and facilities may charge more, reflecting the higher level of service quality they provide.

Services Offered:

Some common variances in service offerings include:

- Basic engine checks

- Oil changes

- Replacement of impellers

- Full engine overhauls

Pricing Models:

- Flat Rate: Some providers offer a set price for specific services, giving clarity on expenses.

- Hourly Billing: Charges based on the actual time spent can be susceptible to the complexity of the service.

Providers may offer different tiers of service packages, from basic maintenance to premium options that include additional checks and replacement parts. It’s important for boat owners to consider the reputation, location, and expertise of a service provider when determining the potential cost of boat engine servicing.

Geographical Influence on Service Costs

The cost of servicing a boat engine can be significantly influenced by geography. Boating experts with 20 years of experience observe that service rates may vary depending on the region and locality. Here’s how geography plays a role:

- Local Economy: In areas with a higher cost of living, labor costs generally increase, leading to pricier services.

- Availability of Services: Remote regions with fewer marine mechanics may charge more due to lack of competition.

- Marina Fees: Marinas in prime locations with more amenities are likely to have higher maintenance fees.

Cost Fluctuations by Region:

| Region | Cost Variation Factor |

|---|---|

| Coastal Areas | Higher due to saltwater corrosion preventive measures |

| Inland Marinas | Potentially lower where freshwater is prevalent |

| Urban Centers | Increased costs linked to higher marina fees |

| Rural Areas | Possible premium for accessibility to services |

Price differences are also affected by local demand. Areas with a high concentration of boats may offer competitive rates, while mechanics in areas with fewer boats might charge more. Importantly, marinas with specialized services for certain types of engines could also influence the overall service expense.

Marine professionals routinely emphasize the importance of considering operational cost implications before choosing a boating location. It’s prudent to investigate regional pricing and factor in these potential variances when budgeting for engine maintenance.

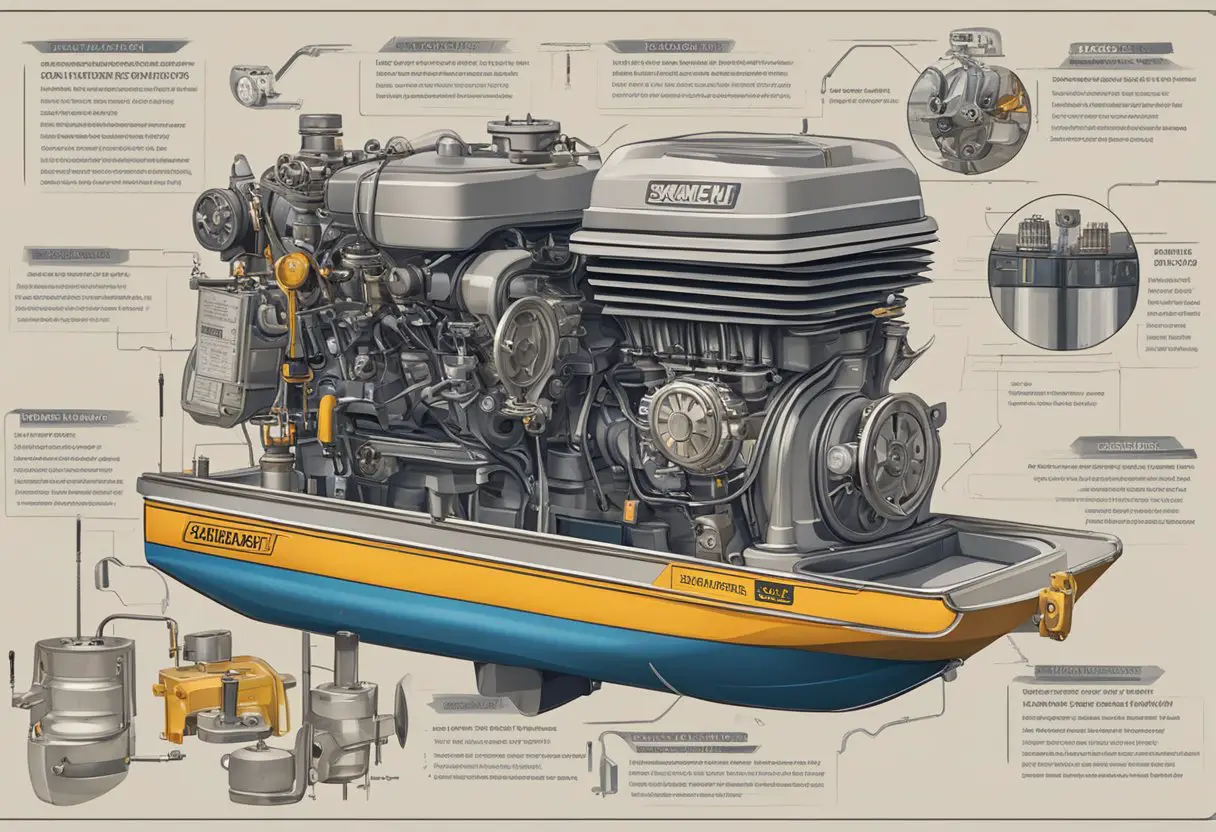

Type of Boat Engine

With two decades of boating experience, they have considerable insights into the various types of boat engines. Their expertise covers everything from simple outboard motors to complex inboard engines. Here’s a breakdown of the main categories:

Outboard Motors: Consisting of a single unit that contains the engine, gearbox, and propeller, these are mounted on the stern of the boat. They’re popular for their portability and ease of maintenance. Generally, they range from small horsepower engines suitable for dinghies to larger ones for speedboats.

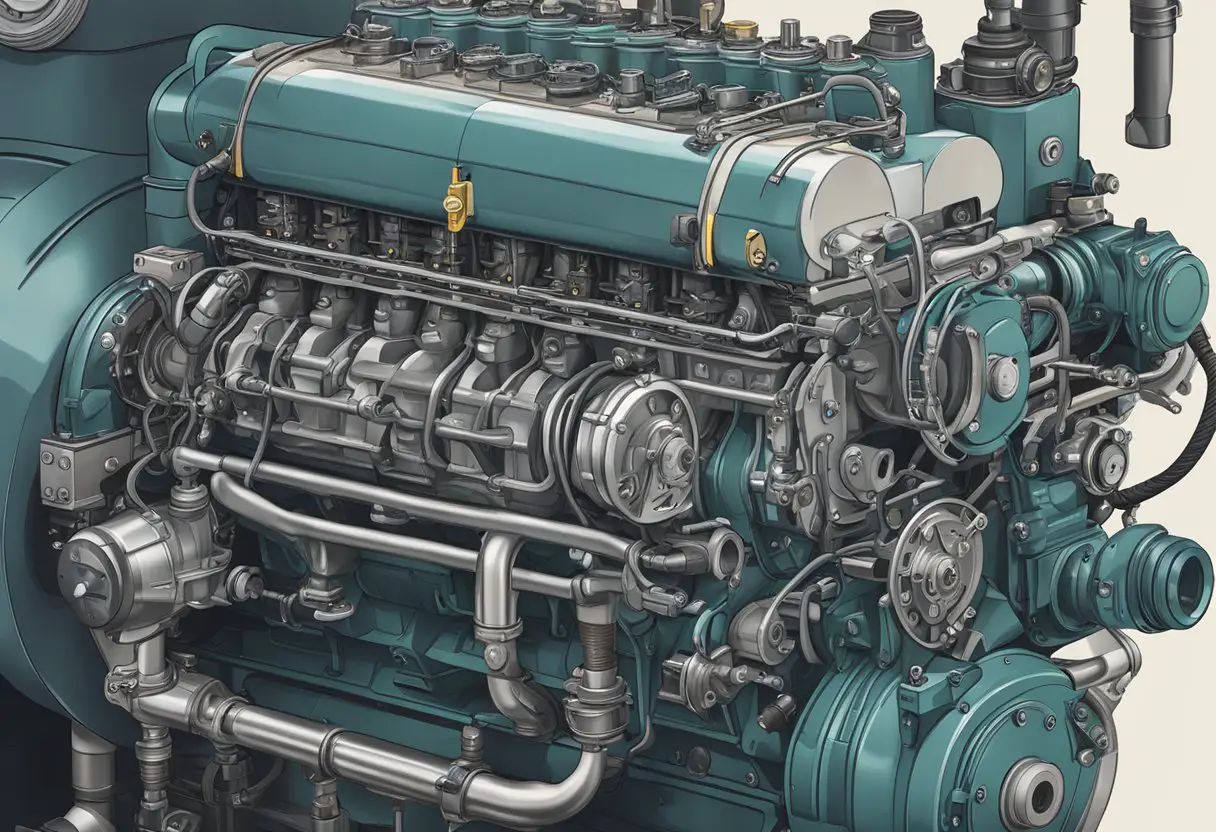

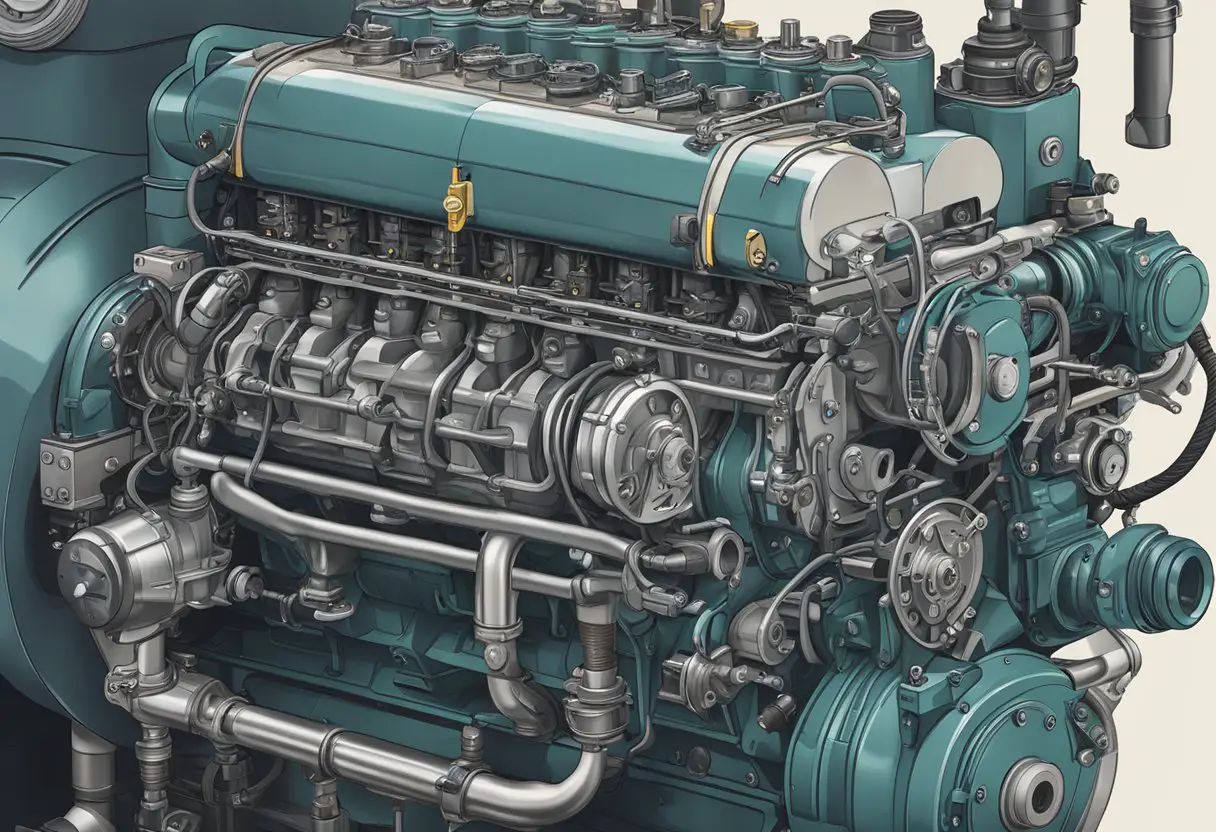

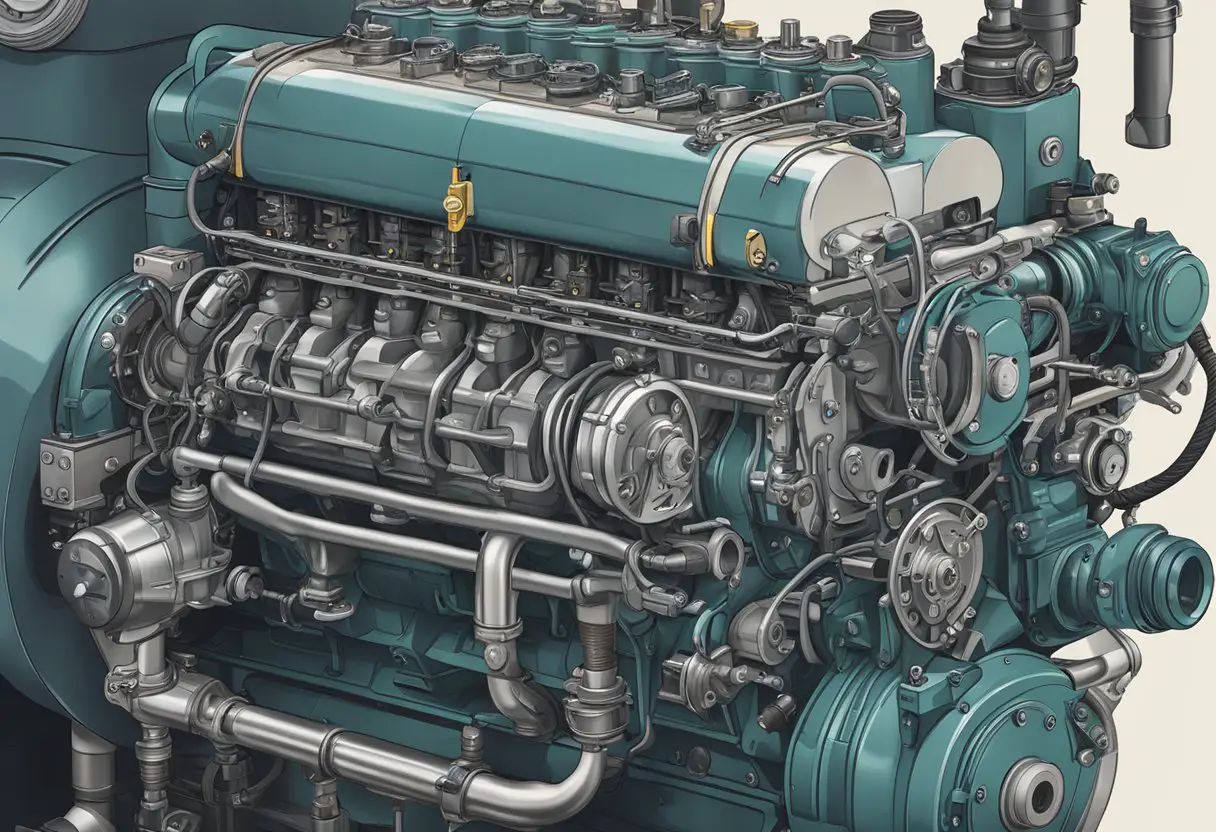

Inboard Motors: Integrated within the hull, these engines offer better balance and are typically used in larger vessels. They are connected to a propulsion screw outside the hull. Maintenance of inboard engines often requires more expertise due to their more complex setup.

Sterndrive (Inboard/Outboard): Combining features of both inboard and outboard motors, sterndrives have the engine mounted inside the boat with the drive unit outside. This setup offers a balance of power and maneuverability.

Jet Drives: These engines draw water from beneath the boat and then forcefully expel it through a nozzle at the stern, propelling the boat forward. Jet drives are known for their shallow draft and ability to operate in waters where propellers might be damaged.

Here are the general maintenance implications:

-

Outboard Motors: Regular maintenance includes oil changes, filter replacements, and gear lubrication. The cost of servicing this engine type can vary based on the engine’s horsepower and whether the work is done professionally or DIY.

-

Inboard Motors: They often require comprehensive services such as belt, impeller, or spark plug replacement and more intricate work on the engine itself.

-

Sterndrive: The maintenance often involves attention to both the engine and the drive unit, requiring a broad range of servicing tasks.

-

Jet Drives: Typically, these require less maintenance but might need service for the impeller and internal drive components.

Choosing the right type of engine and understanding its maintenance needs is essential for any boat owner.

Time Interval Between Services

Boat engine service frequency is influenced by both usage and time. A boater with 20 years of experience will attest that engines need routine check-ups either after a certain number of operating hours or at regular time intervals, whichever comes first.

Annual servicing is a standard recommendation for the casual boater, ensuring that the engine maintains its performance and longevity. According to Quicknav, routine engine service is generally recommended on an annual basis.

For those using their vessels more frequently, the engine might require attention after every 100 hours of operation. This 100-hour service is vital, especially for high-demand scenarios, as noted by Boats.net’s checklist. It is a safeguard against wear and tear that accrues from regular use.

- Light Use: Service once per year or after every 100 operating hours

- Regular Use: Service every 100 operating hours or at least twice yearly

Boaters should understand that intervals may vary depending on the engine type and manufacturer’s guidelines. It’s crucial to consult the owner’s manual or a professional mechanic for the most accurate service timetable specific to one’s boat engine.

Should the boat be used in harsh conditions like saltwater, service intervals should be more frequent. Saltwater accelerates corrosion and can lead to more significant issues if regular maintenance is overlooked. Boaters who do not store their vessels appropriately in harsh environments will require a more diligent approach to maintenance.

The key takeaway for any boater, whether they’re seasoned or new to the lifestyle, is that regular engine service is non-negotiable for safe and reliable boating.

DIY vs. Professional Service

When considering boat engine service, boat owners can opt for either DIY maintenance or professional servicing. Drawing from 20 years of boating experience, it’s important to understand the differences and cost implications.

DIY Boat Engine Service:

- Cost-effective: Owners may spend significantly less maintaining their boats themselves.

- Required Skill: A good understanding of engine mechanics is necessary.

- Time Commitment: Time must be allocated for research and the actual work.

- Tools and Parts: Owners are responsible for purchasing the correct tools and parts.

Professional Boat Engine Service:

- Higher Cost: Expect to pay more for professional services, sometimes 3-5 times more than DIY.

- Expertise: Professionals provide skilled service, which is important for complex tasks.

- Convenience: Owners save time as professionals handle all aspects of the service.

- Guarantee: Work is often guaranteed, giving owners peace of mind.

| Service Type | DIY | Professional |

|---|---|---|

| Cost | Lower | Higher |

| Skill Required | High | Handled by Experts |

| Time Investment | Significant | Minimal (handled by service provider) |

| Tools & Parts | Self-provided | Provided by service |

In essence, the choice between DIY and professional boat engine service hinges on one’s mechanical skill level, the value of time, and cost considerations. Boat owners must weigh their ability to handle maintenance tasks against the convenience and quality assurance offered by professional mechanics.

Warranty and Service Plans

Boat engine service costs can be mitigated by understanding and utilizing warranty and service plans. A standard manufacturer’s warranty typically covers boat engines for a specific period, which can range from one to several years. This warranty is primarily against manufacturing defects and may offer comprehensive coverage during its active period. For example, Mercury Marine Warranties provide a detailed chart outlining their coverage duration by product.

Beyond standard warranties, boat owners can also consider extended service contracts, which are akin to health insurance for your boat. These plans cover the costs of unforeseen repairs after the manufacturer’s warranty expires. It’s crucial to thoroughly comprehend the terms, as these contracts often include deductibles and may exclude specific incidents or actions, such as engine removal from the boat.

Here is how a standard service plan may break down:

- Deductibles: $25 to $50 per incident

- Coverage: Varies widely in terms of parts and labor

- Transferability: May allow transfer to a new owner

Boat Trader offers extended marine service contracts to curtail the financial burden of mechanical breakdowns. It is imperative that boat owners carefully evaluate the cost-effectiveness of these plans to ensure they fit their specific needs.

Experienced boat owners, those with two decades of boating know-how, often advise to compare service contracts. They should provide clear value and align with the owner’s usage patterns, such as frequent long voyages where the risk of engine troubles is higher. Often neglected, but vital, is the credibility of the company offering the warranty or service plan. A reputable provider means greater peace of mind.

Frequently Asked Questions

Drawing on 20 years of boating experience, this section aims to address the most common inquiries boat owners have regarding the costs of engine servicing.

What is the typical cost range for servicing an outboard motor?

Outboard motor servicing typically ranges from about $100 for basic maintenance to upwards of $1000 for more comprehensive services, including impellers, based on regional service rates.

What expenses are involved in a 100-hour service for a Mercury outboard engine?

A 100-hour service for a Mercury outboard engine often involves oil changes, gear lube replacement, and filter inspections, which can cost several hundred dollars, depending on the service provider’s rates.

How frequently are boat engine maintenance services recommended?

It is typically recommended that boat owners conduct engine maintenance services every 50-100 hours of use, or at least once per season, to ensure optimal performance and longevity.

What are the expected costs for inboard boat engine servicing?

Servicing inboard boat engines usually carries higher costs due to their complexity, with prices possibly exceeding $1000 for full services, including parts and labor.

Can you estimate the annual maintenance expenses for owning a boat?

Annual maintenance expenses for a boat have been estimated to be between 4-10% of the boat’s purchase price, which can significantly vary based on boat type and usage.

What is a general guideline to budget for boat engine maintenance?

As a general guideline, boat owners should anticipate spending around $2,000 per year on average for boat maintenance, with variations depending on whether the maintenance is DIY or professionally serviced.