Principles of Marine Air Conditioning

Marine air conditioning systems operate on the same basic principles as their land-based counterparts but are specifically designed to handle the unique marine environment. With efficiency and durability in mind, these systems ensure a comfortable climate aboard various types of vessels.

Basic Refrigeration Cycle

Marine air conditioning relies on a refrigeration cycle that consists of several key components: the compressor, condenser, evaporation coils, and expansion valve. Initially, the refrigerant is compressed, elevating its temperature and pressure. The hot, high-pressure refrigerant then moves through the condenser coils, usually cooled by seawater, where it releases heat and changes from a gas to a liquid. After passing through the expansion valve, which reduces its pressure, it absorbs heat from the cabin air in the evaporation coils, effectively cooling the air. Finally, the refrigerant, now a low-pressure gas, returns to the compressor, and the cycle repeats.

Types of Refrigerants

There are multiple types of refrigerants used in marine air conditioning, selected based on their efficiency, environmental impact, and compatibility with marine conditions. Some common refrigerants include R-134a and R-410A, known for their lower ozone depletion potential and global warming impact, making them more environment-friendly options. It’s crucial for the refrigerant to be well-suited for marine applications, considering factors such as the system’s exposure to salt water and the need for corrosion resistance.

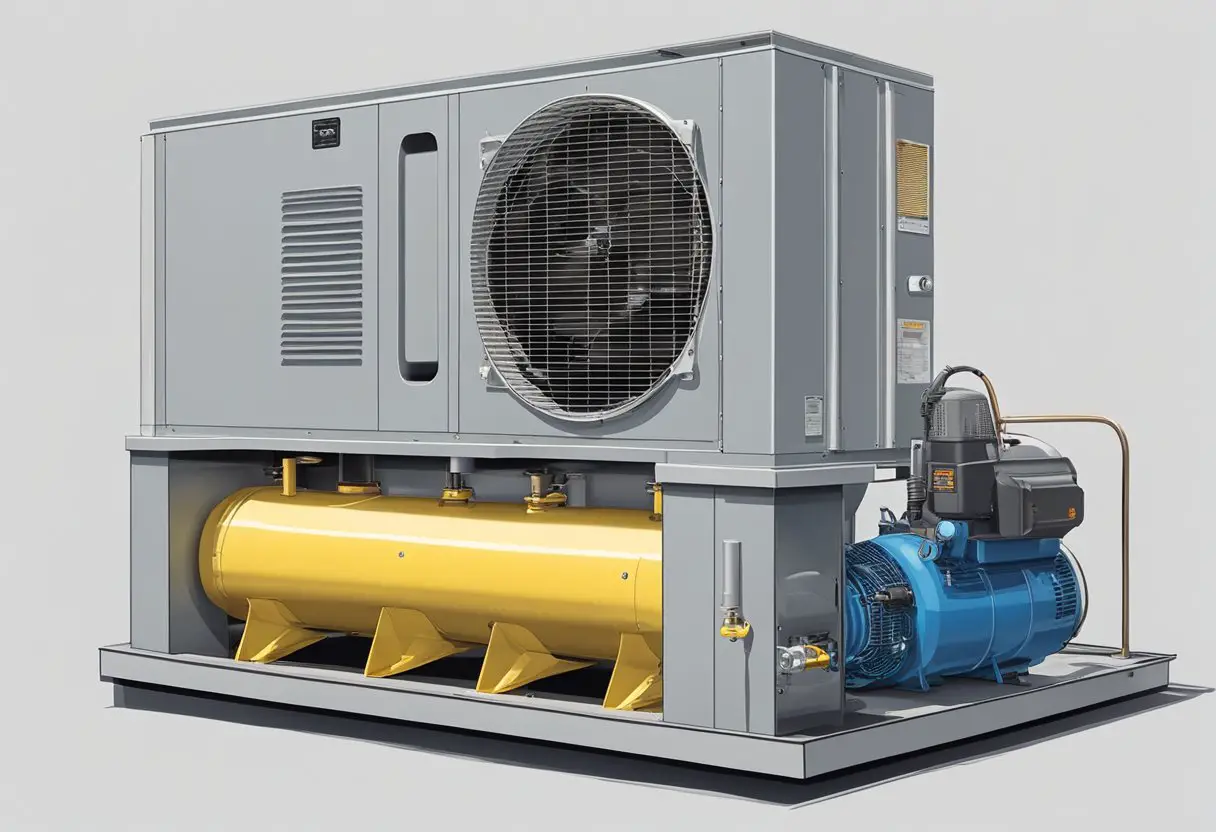

Components of a Boat AC Unit

A boat AC unit operates through a complex interaction of components, each playing a critical role in cooling the air. Understanding these parts is essential for grasping how marine air conditioning systems function effectively.

Compressor

The compressor is the power unit of the air conditioning system, which takes in low-pressure refrigerant gas and compresses it into a high-pressure, high-temperature gas. This process is integral as it prepares the refrigerant to release heat rapidly when it flows into the condenser.

Condenser

Following the compressor, the refrigerant travels to the condenser, where it releases the absorbed heat to the outside environment. In a boat AC unit, the condenser typically resides as part of the outdoor unit, dispensing heat through its coils into the surrounding seawater or air.

Evaporator

The evaporator acts as the site where the cooling effect is felt. Here, the refrigerant transitions from a liquid to a vapor, absorbing heat from the cabin air in the process. This chilled air is then delivered back into the boat, significantly lowering the temperature.

Expansion Valve

Located between the evaporator and condenser, the expansion valve controls the flow of the refrigerant. By modulating the amount of refrigerant entering the evaporator, it assists in maintaining optimum pressure and temperature levels throughout the system.

Types of Boat AC Systems

Boat air conditioning systems are essential for maintaining comfortable temperatures inside the cabin during warm weather. These systems vary in complexity and installation types, ranging from compact, self-contained units to more complex setups like chilled water systems and split system units.

Self-Contained Units

Self-contained units are the most common air conditioning systems found on small to mid-sized boats. These units contain all components—compressor, condenser, evaporator, and controls—within a single box. Installation is typically straightforward, as they are designed to fit into compact spaces without extensive modification.

Chilled Water Systems

Chilled water systems serve larger vessels where multiple areas need cooling. These systems rely on a central chiller that cools water, which is then piped through the boat to air handlers in different zones. It is a flexible option, allowing for individual temperature control of each cabin or space.

Split System AC Units

Split system AC units divide the condenser and evaporator into separate units, connected by refrigerant lines. The condenser unit is usually installed in an engine room or other mechanical spaces, while the evaporator is placed in the living spaces. This separation can result in more efficient cooling and quieter operation within the cabin area.

Power Requirements and Efficiency

Marine air conditioning systems have specific power demands and efficiency metrics that are crucial for optimal operation and sustainability. Understanding these can aid in selecting the right unit for a vessel and ensuring efficient energy use.

Electrical Power Considerations

Boat air conditioning units operate using either direct current (DC) or alternating current (AC) power sources. The choice between DC or AC power depends on factors such as the boat’s existing electrical system and the power availability on board. AC units typically require a generator or shore power connection due to higher energy requirements, whereas DC units can be directly connected to the boat’s battery system. For instance, running an AC unit from a DC power source involves an inverter, which introduces approximately a 15% inefficiency due to energy conversion and heat loss.

Energy Efficiency Ratings

The efficiency of marine AC units is often indicated by their energy efficiency rating. This rating can help determine how much power the unit will consume under normal conditions. It’s a critical factor in managing long-term operational costs and reducing the environmental impact. A higher rating signifies greater efficiency, translating to lower energy consumption for the same level of cooling performance. Users should note that all marine air conditioning systems incorporate the basic components of an evaporator, compressor, condenser, and expansion valve, with the efficiency largely depending on the quality and configuration of these components.

Installation Considerations

Installing a boat AC unit requires meticulous planning to ensure efficient operation and longevity. These considerations focus on maximizing space efficiency, ensuring proper airflow, and optimizing insulation.

Space Requirements

Boat air conditioning systems necessitate a balance between available space and the unit’s size. Boaters must identify a location that not only fits the physical dimensions of the AC unit but also allows for maintenance access. According to Boat AC guidelines, installation spaces need to cater to both the unit and additional components such as ductwork and electrical connections.

Ventilation and Air Flow

Effective ventilation is essential for an air conditioning system to function properly. Installations should include active ventilation systems, like fans that promote continuous air movement, powered by the boat’s energy or solar power. Moreover, Boat Trader emphasizes the importance of incorporating passive ventilation components such as grilles or ports to aid natural airflow.

Insulation

Proper insulation directly impacts the efficiency of marine air conditioning systems. Every section of the boat where the unit operates should be well-insulated to prevent loss of cool air. As detailed by the BoatUS guide, selecting the right insulation material and ensuring airtight seals around ducts can significantly improve the unit’s performance and reduce energy consumption.

Maintenance and Troubleshooting

Maintaining the air conditioning system on a boat is crucial for performance and longevity, while effectively troubleshooting can save time and resources. Here are specific tasks and solutions aimed at keeping boat AC units operational.

Regular Maintenance Tasks

Monthly Filter Cleaning: Filters must be cleaned monthly to ensure efficient airflow, as a clean filter greatly impacts the system’s performance. Boat owners should vacuum or wash their filters following the guidelines in the owner’s manual to prevent blockage and maintain air quality.

Condenser Coil Maintenance: To prevent overheating and ensure effective cooling, it’s important to keep the condenser coils free from debris and obstruction. A clean system is critical for proper airflow and unit efficiency.

Common Problems and Solutions

Clogged Thru-Hull: A clogged thru-hull restricts the AC unit’s ability to draw raw water, leading to reduced cooling. Inspecting and cleaning the thru-hull will resolve this issue and can prevent further damage to the system.

Power Source Issues: If an AC unit operates correctly on shore power but fails on generator power, the issue might not be the air conditioning system itself. Ensure the generator is running correctly and providing sufficient power. Other appliances functioning normally can indicate that the issue lies within the AC unit’s power setup or its own electrical components.

By adhering to regular maintenance tasks and addressing common problems quickly, boat AC systems can function reliably, providing necessary comfort onboard.

Climate Control Integration

Integrating climate control systems on boats involves the synchronization of various components to maintain the desired onboard temperature and humidity levels. Critical to this integration are thermostats and control panels, which allow for precise adjustments, and automated climate systems, which provide consistent and energy-efficient temperature management.

Thermostats and Control Panels

Thermostats serve as the main interface for boat owners to set and monitor the desired environmental conditions. Control panels often feature intuitive interfaces, with digital displays allowing users to easily adjust temperature settings. Advanced models might include touch-screen capabilities and can be integrated with mobile applications, offering the convenience of remote adjustments.

Automated Climate Systems

Automated climate systems rely on a set of predefined rules to regulate cabin temperature. They adjust the operation of the air conditioning unit based on various inputs, such as time of day, ambient temperature, and humidity levels. These systems can significantly enhance energy efficiency by operating only when necessary, reducing the energy consumption that would otherwise occur with continuous manual adjustments.

Frequently Asked Questions

In this section, readers will find answers to common inquiries about the workings of marine air conditioning systems, their power requirements, and the unique features they offer for maritime environments.

What is the operating principle behind marine air conditioning systems?

Marine air conditioning systems utilize water to transfer heat instead of using air. They operate by circulating cool water through coils to absorb heat from the cabin, then expelling the warmed water back into the ocean or lake.

How much electrical power is typically required to run a marine air conditioner?

The power required can vary widely, but a typical marine air conditioner may need between 5,000 to 16,000 BTUs per hour, equating to an electrical draw of roughly 500 to 1,500 watts under normal conditions.

Is it possible to power a boat air conditioning unit with a 12-volt system?

It is typically challenging to power a standard marine air conditioner directly with a 12-volt system due to the high power consumption. Many systems use 110 or 220 volts AC power, and 12-volt systems usually require an inverter or generator.

Can marine air conditioners run efficiently on just batteries, and if so, for how long?

Marine air conditioners can run on batteries, but they are energy-intensive and may drain batteries quickly. The duration depends on battery capacity and the air conditioning system’s power consumption, which limits operational time to a few hours at best.

What is a reverse cycle marine air conditioner, and how does it differ from standard units?

A reverse cycle marine air conditioner can provide heating in addition to cooling. They are equipped with a reversing valve which allows the refrigeration cycle to be reversed, providing warm air in colder conditions.

What are the expected lifespans of marine air conditioning systems?

The lifespan of marine air conditioning systems can extend to 15-20 years with proper and regular maintenance. Factors that affect longevity include the quality of the system, environmental conditions, and how well the system is maintained.